SCD employs the SolidWorks program for part design, assembly, and drawing, adhering to the American Society of Mechanical Engineers (ASME) Y14.5 GD&T standard.

❖ Engineering Design

We can create detailed drawings for a single component, an assembly of multiple parts, or an entire system of assemblies

Molding: Rotational, Injection (over and multi-shot molding), Blow, Compression, Extrusion, Thermoforming

Precision CNC Machining: Lathes and Turning, Milling, Laser, EDM, and Plasma Cutting Machines

Metal Forming: Curling, Bending, Ironing, Laser Cutting, Hydroforming, Punching, and design for metal casting

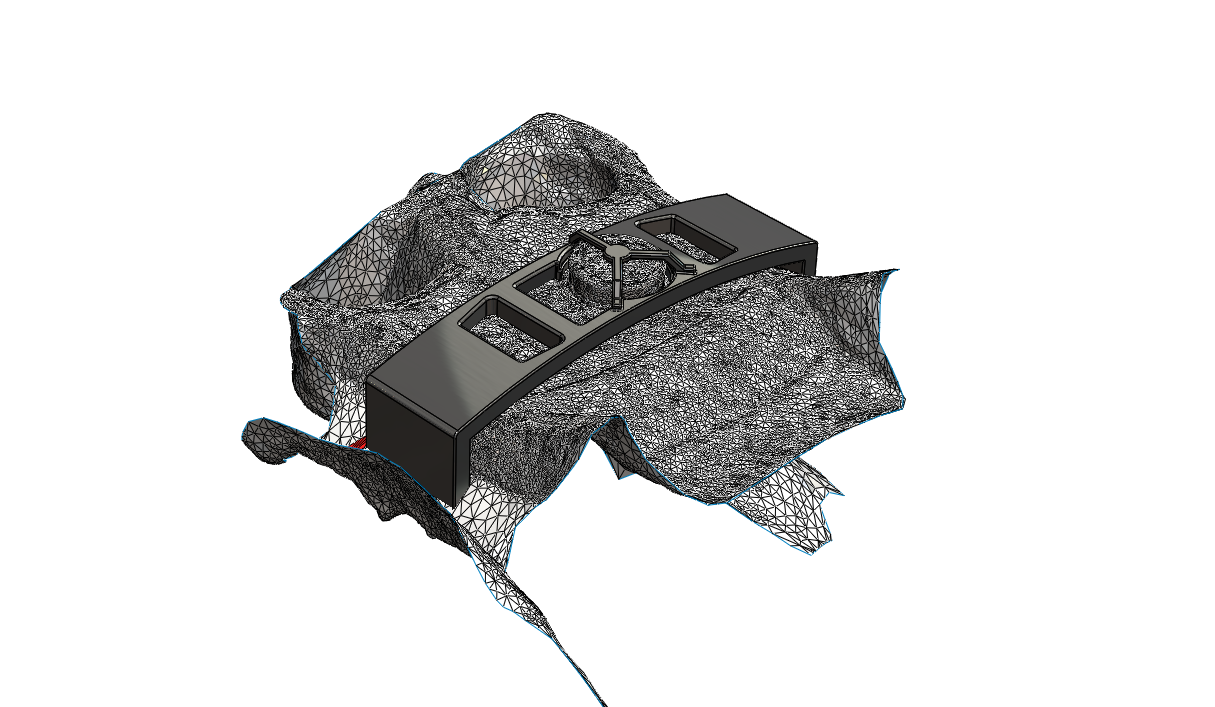

❖ Reverse Engineering

Thorough analysis of part composition and assembly construction

With precision, SCD can generate models and detailed drawings from existing physical parts or from any 2D/3D file

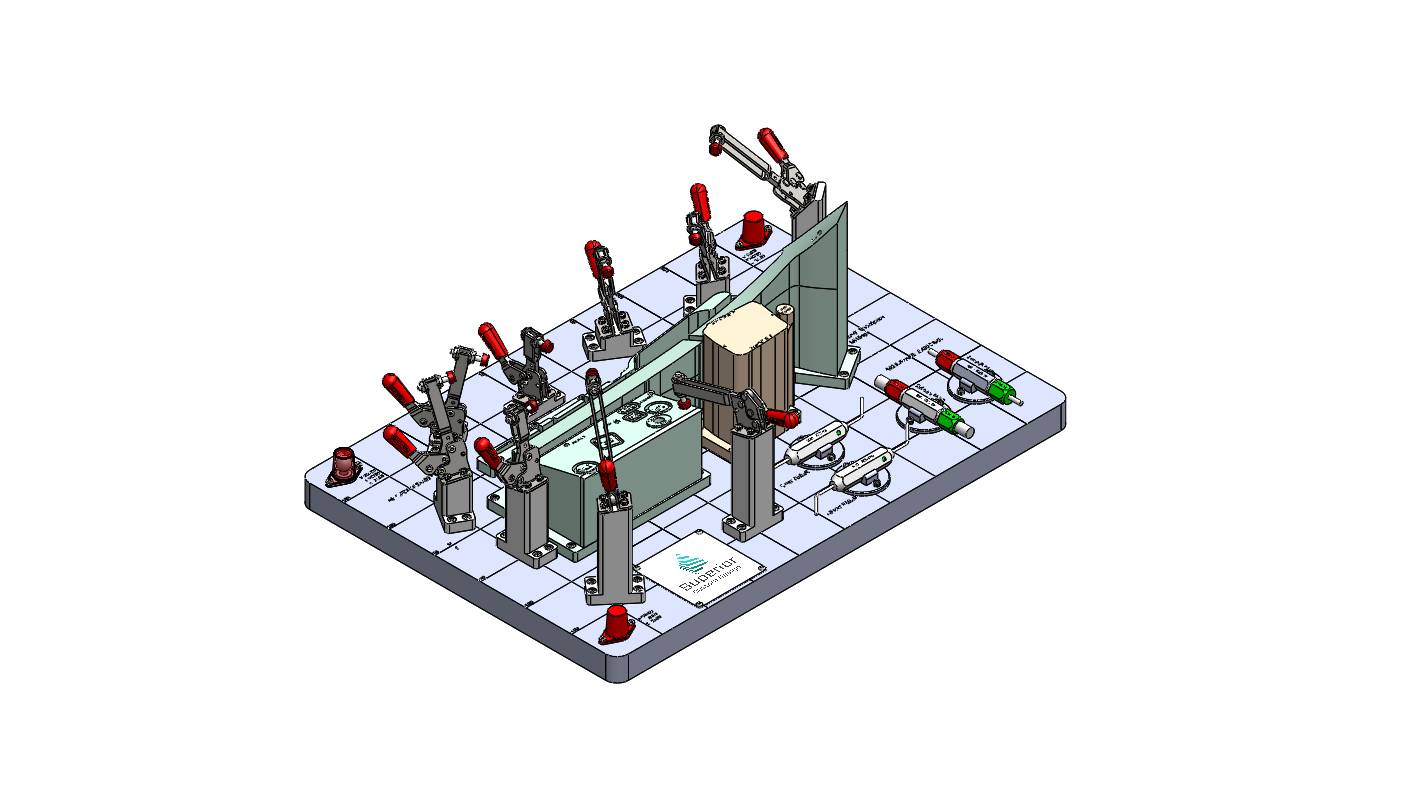

❖ Functional Fixtures and Gage Design

Robust and efficient fixture for any part or assembly

Complete gage design referencing drawing or part with Geometric Dimensioning and Tolerancing

Welding fixture for any part or assembly. Adjusting workpieces in any orientation for welding

SCD has reliable certification contacts

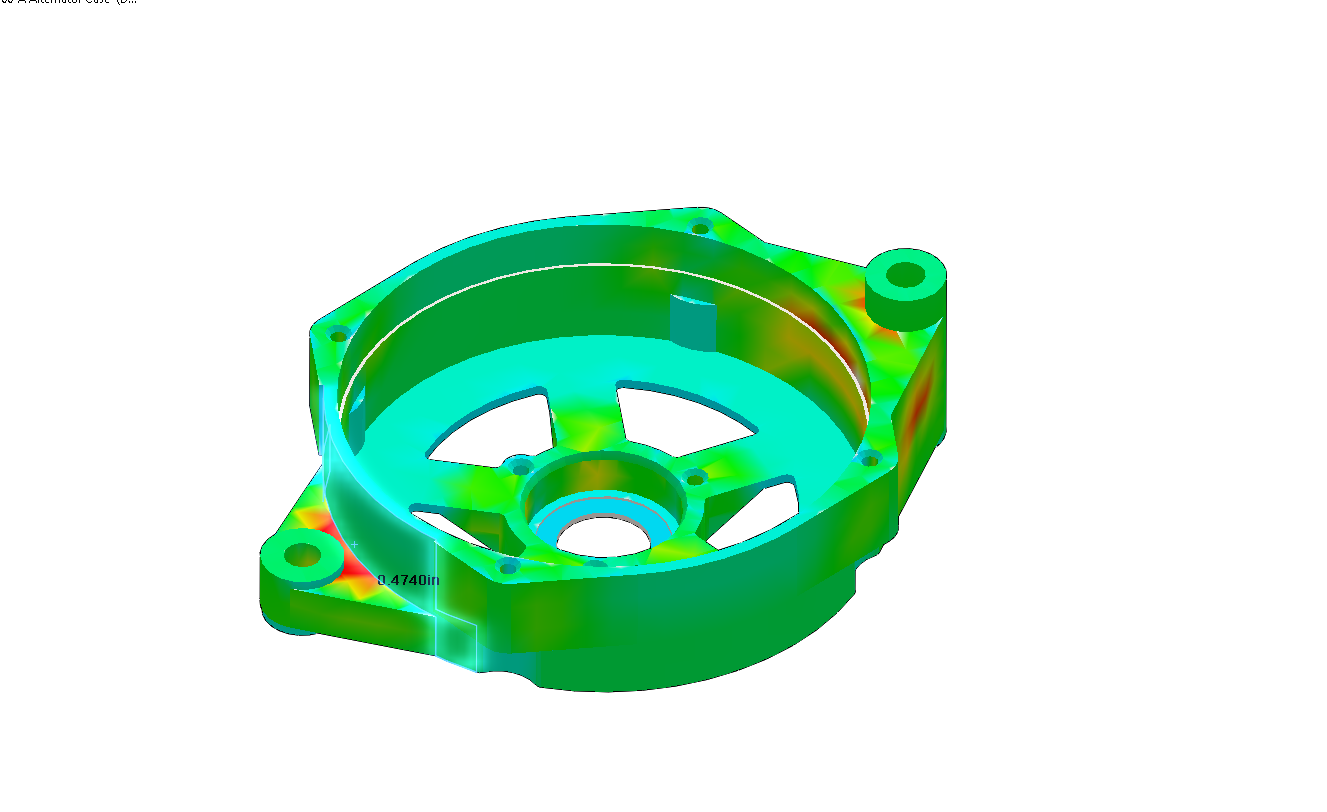

❖ Engineering DFM / Analysis

Design For Manufacturing with draft and thickness analysis

Part expectancy with Fatigue and Finite Element Analysis

❖ 3D Printing

FDM - FUSED DEPOSITION MODELING

Printing Accuracy: +/-0.1 mm (0.004 in)

Materials in all different colors

Common: PLA, ABS

High Performance: ABS-GF25, PETG-T, ASA, ASA-AERO, TPU95A-HF, PP

Industrial Grade: ULTRA PA (Nylon), PC/ABS-FR, PLA-CF, PET-CF, PAHT-CF, PA12-CF

❖ SCD has reliable manufacturing and fabrication partners in molding, machining, tool & die, welding, foam, prototyping, and more.

Automotive gage/fixture GD&T

Control Valve

Golf Cart Rack Fixture

Sand Filter Part 1

Sand Filter Part 2

Chuck assembly

3D scan GMC Terrain

Quadruple Portal

Rotating snap fit

Roundness gage