Reverse Engineering

Thorough analysis of part composition and assembly construction

With precision, SCD can generate drawings from existing parts or assemblies (or vice versa)

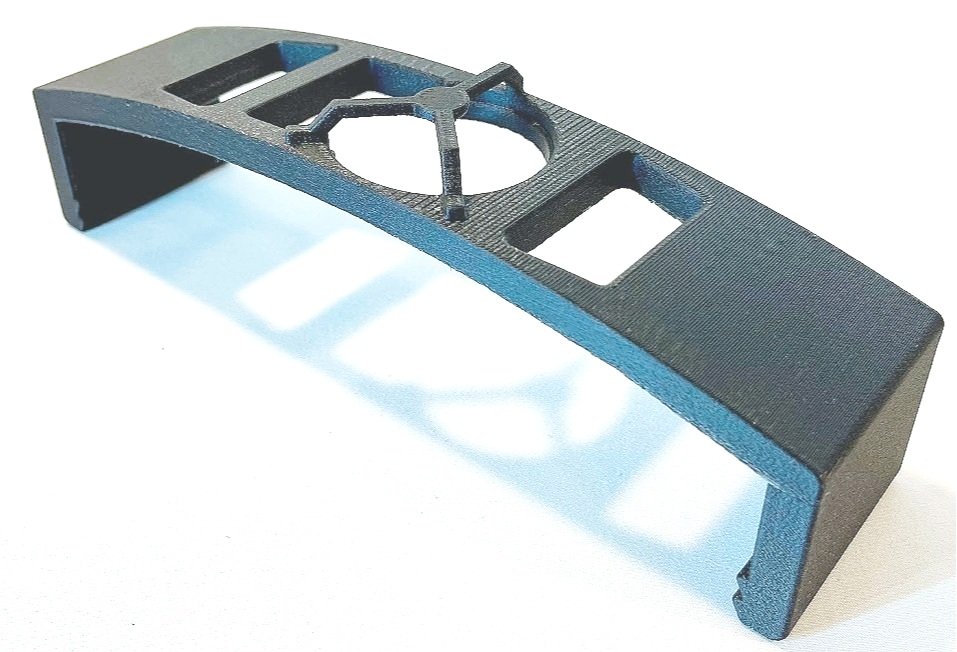

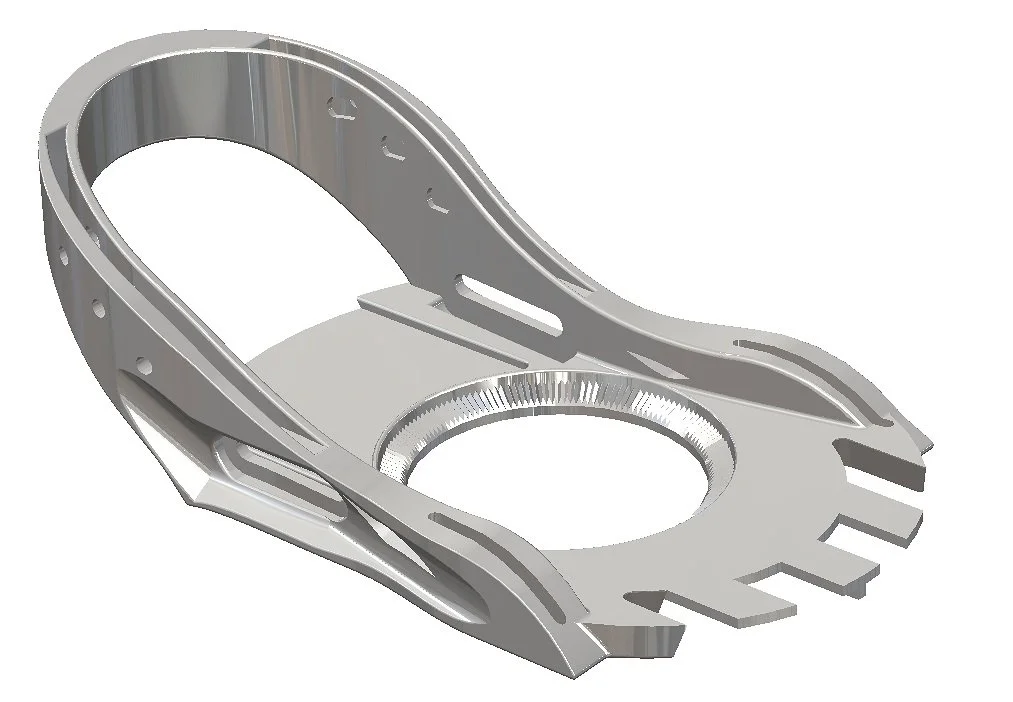

Reverse engineered motor fan blade. 3D printed a working production part. Installed and working properly running at 3,250 RPM.

Designed a button guard automotive attachment. Reverse engineered GMC Terrain with 3D scanner.

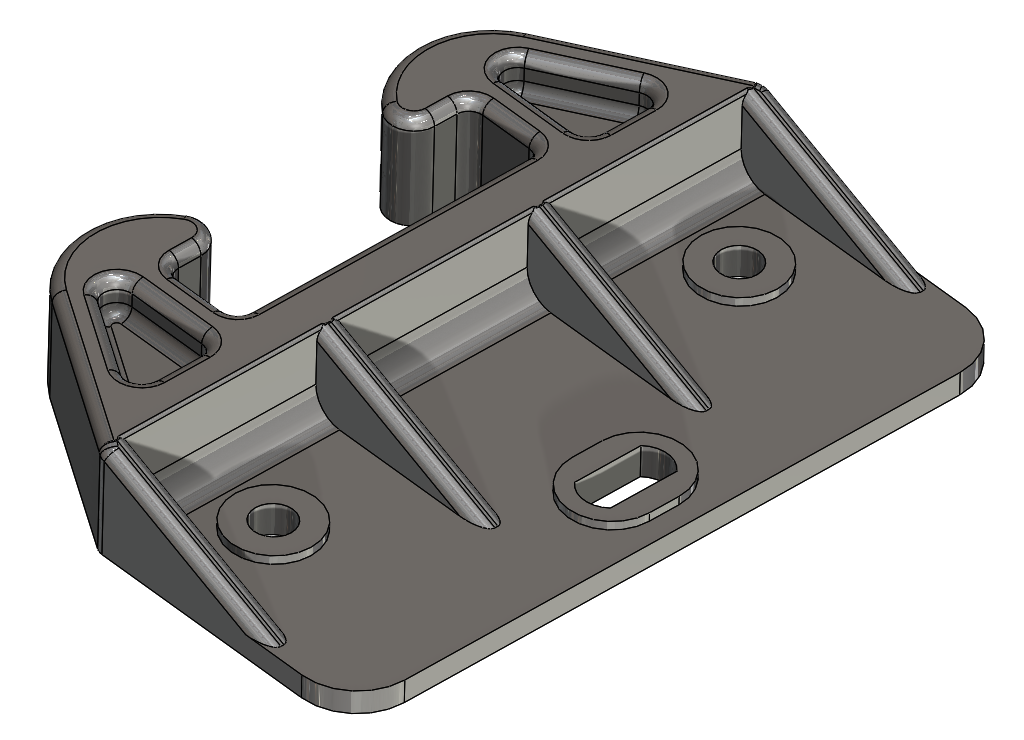

Reverse engineered track drawer guide for slide style drawers. Produced 3D printed parts for customer out of low coefficient of friction material.

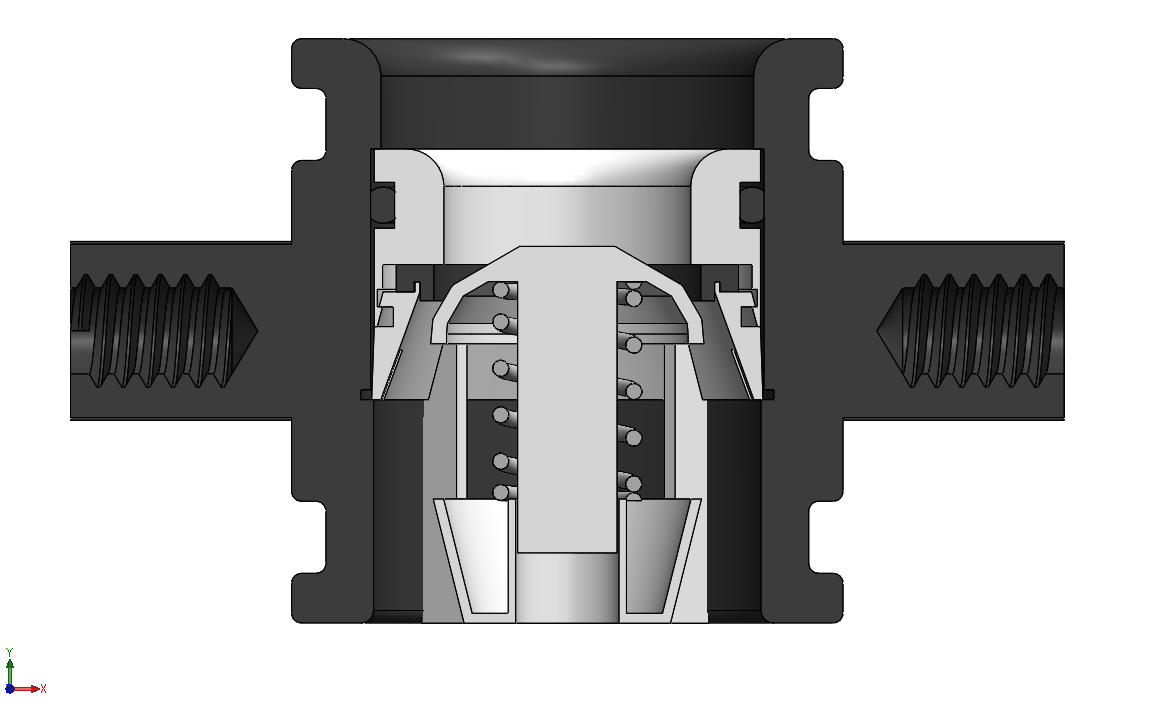

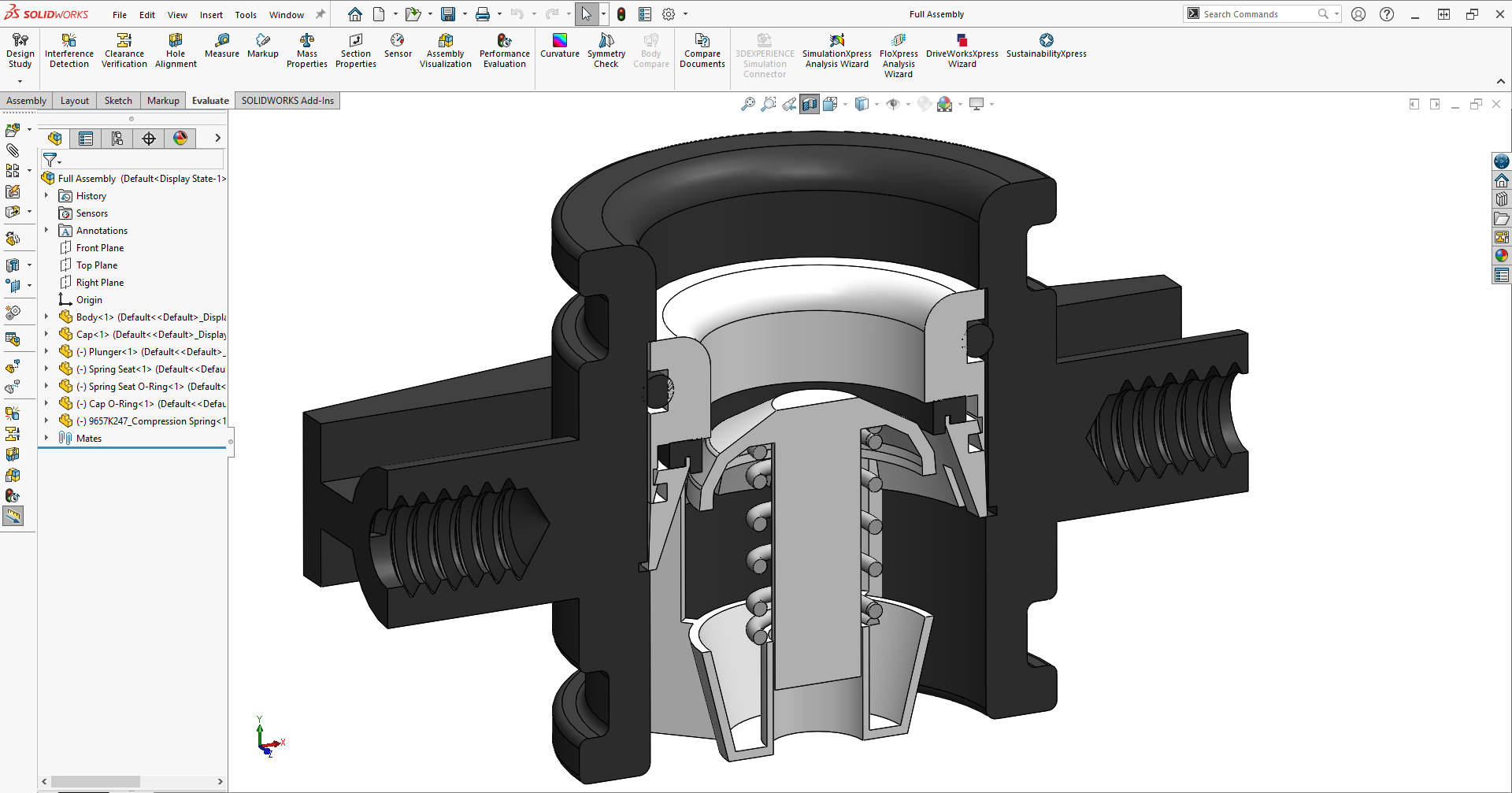

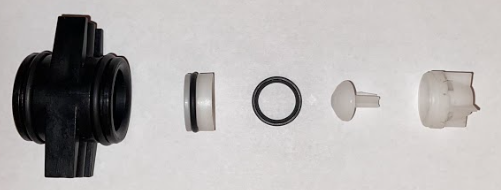

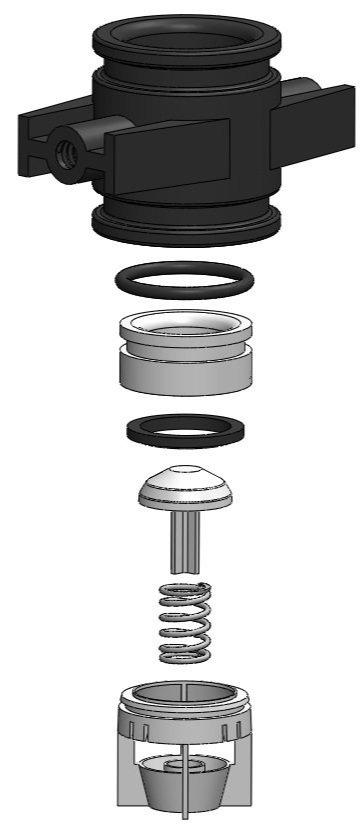

Performed reverse engineering on internal components to facilitate the design of a new molded body for a one-way check valve.

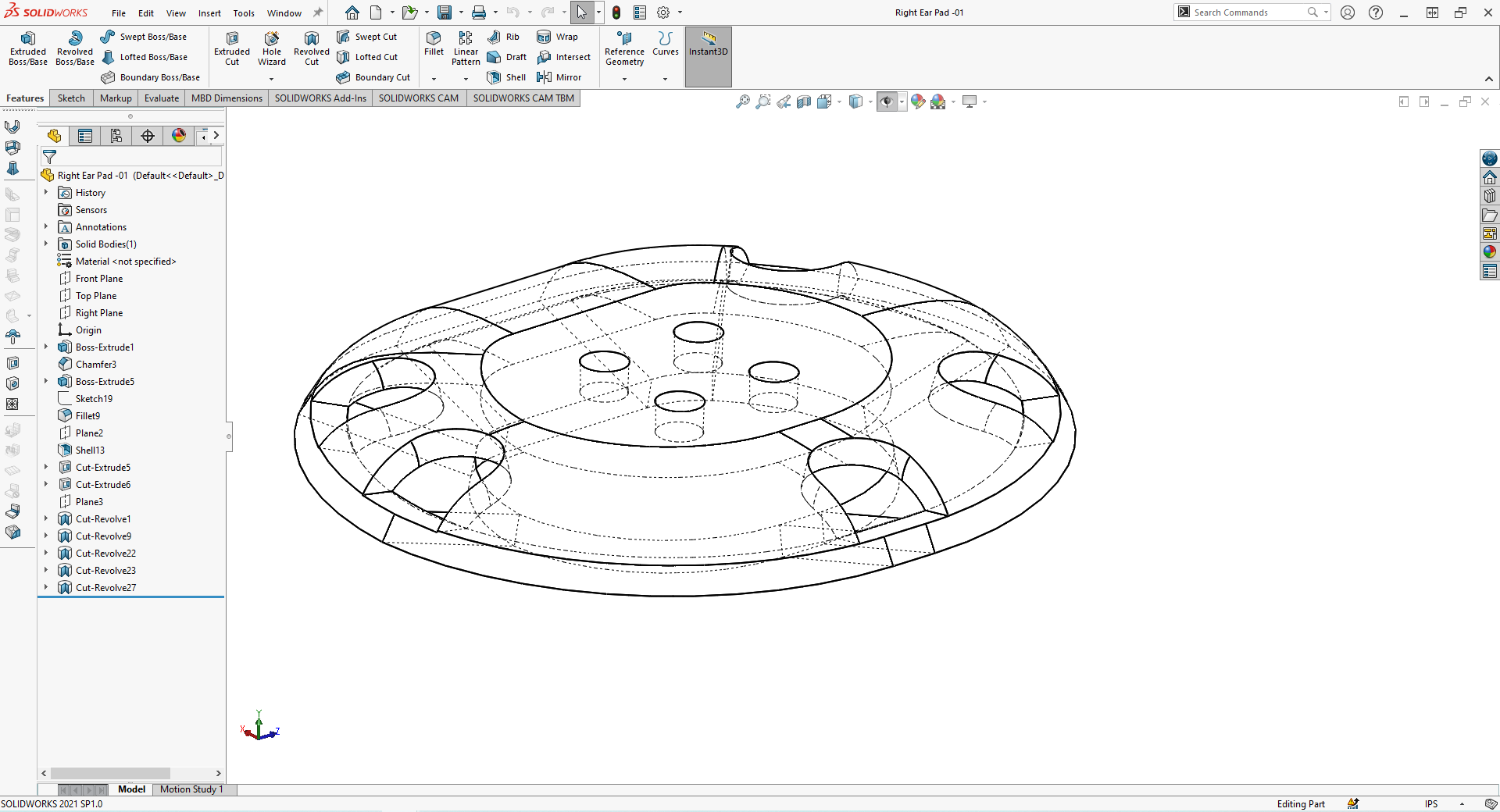

The initial foam product employed compression foam molding along with secondary adhesive. SCD successfully developed an injection foam molding model based on the physical part.

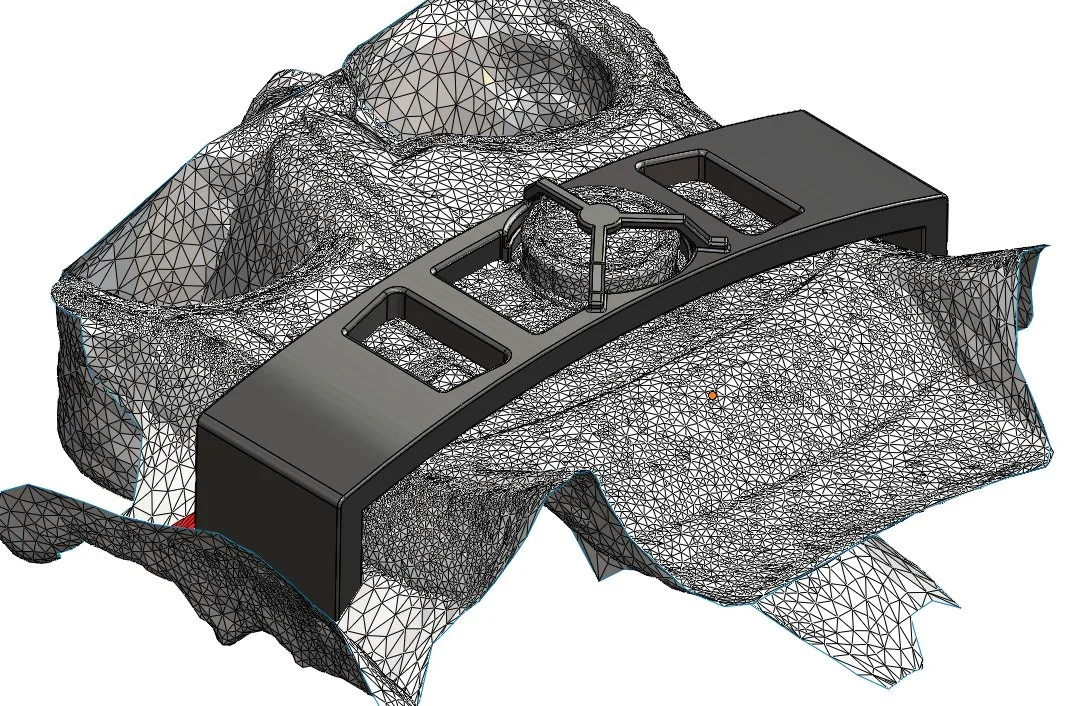

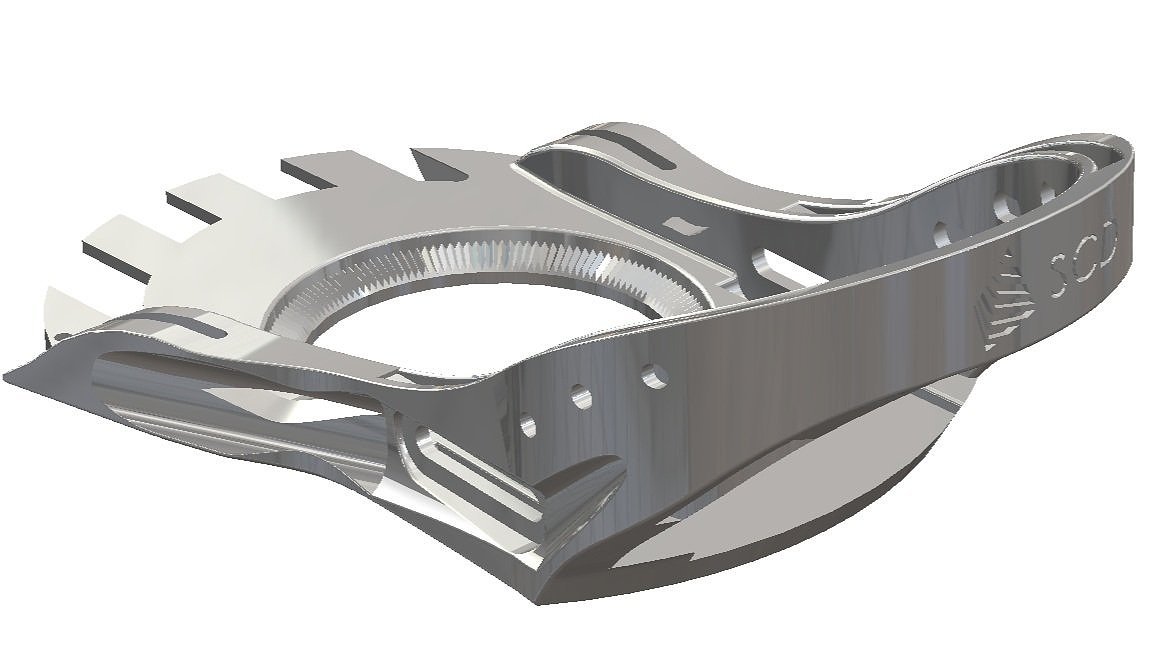

Reverse engineered snowboard binding frame. Analysis fit and function with 3D print of finished model. Printed out of PA12-CF for flexural strength and abrasion resistance.

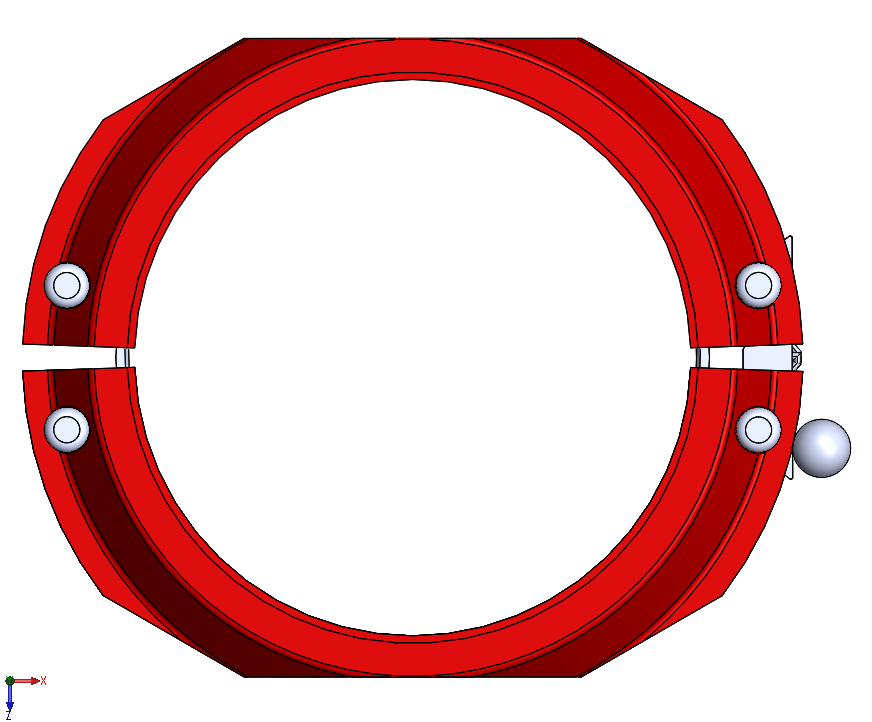

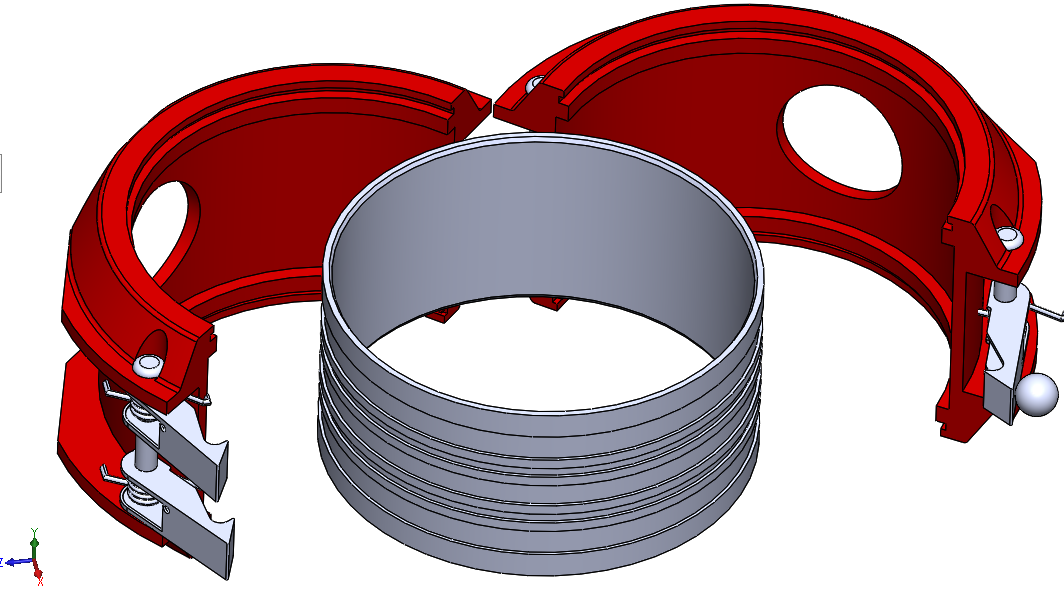

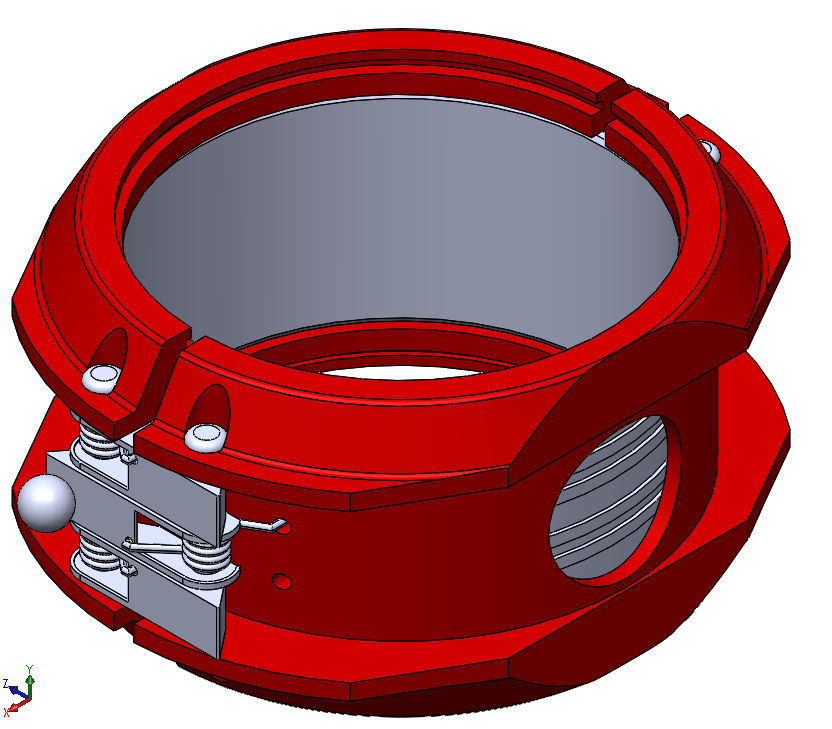

Mock-up of hydraulic clamshell for fluid transfer application.